Welcome to Geekays Auto Components

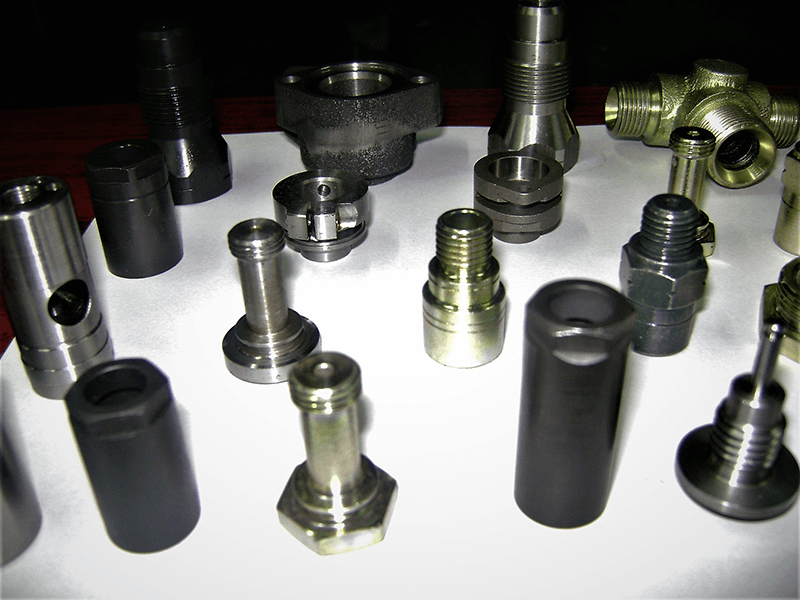

Geekays Auto components (ISO TS 16949 certified) is a precision metal parts supplier to the automotive industry specialising in turned parts, milled parts with secondary operations like turning, drilling , milling , honing , grinding , electroplating, phosphating ,heat treatment etc.High volume parts, repetitive machining,proven quality systems and customer focus on delivery and quality are the major strengths.Precision machining of bar stock, castings, forgings using state of the art CNC machinery.More than 50 CNC machines for contract manufacturing.State of the art resources comprising of CNC turning centers, turn mill centers, swiss turning centers,vertical machining centers , honing machines, gear hobbing, gear shaving, broaching, and a number of conventional production machinery helps in complete manufacture of parts as per print

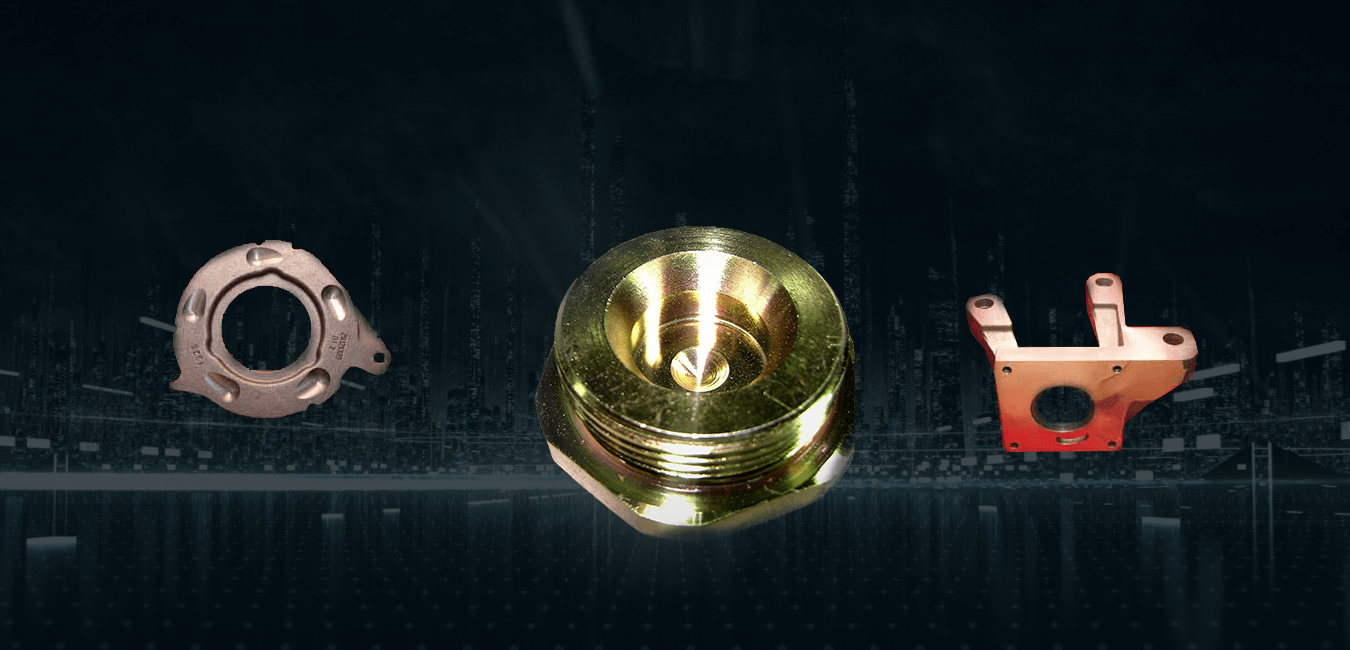

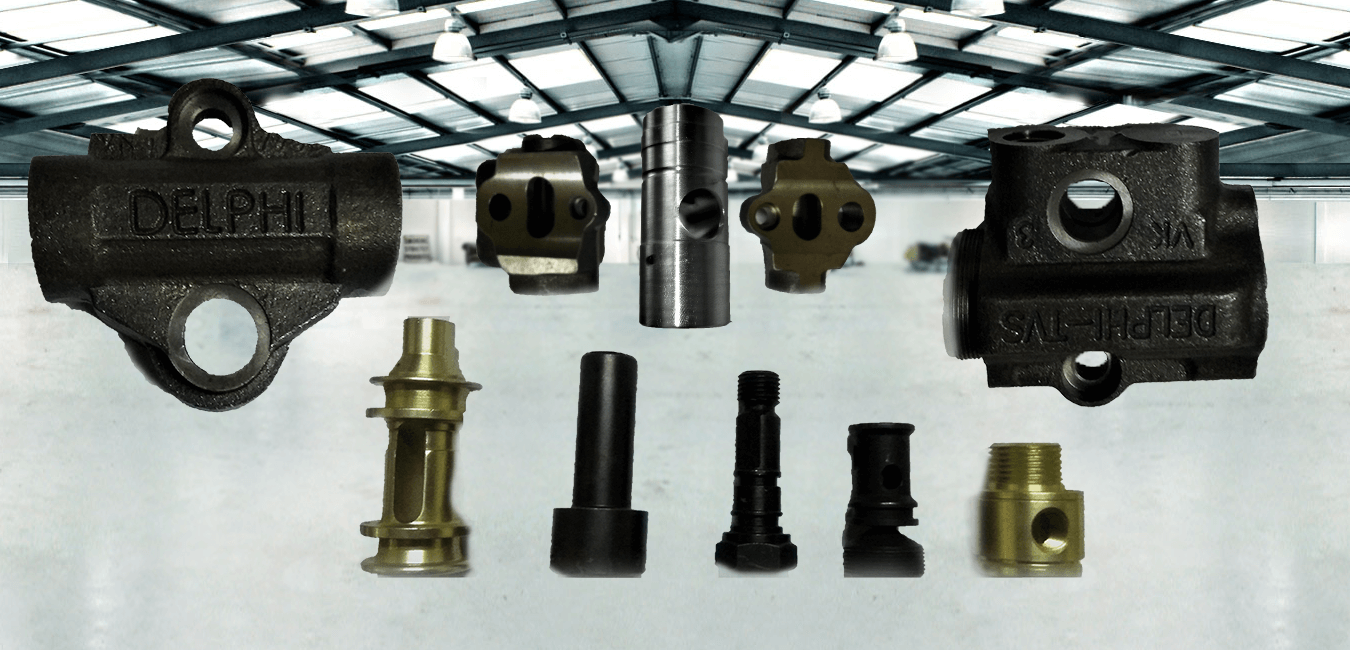

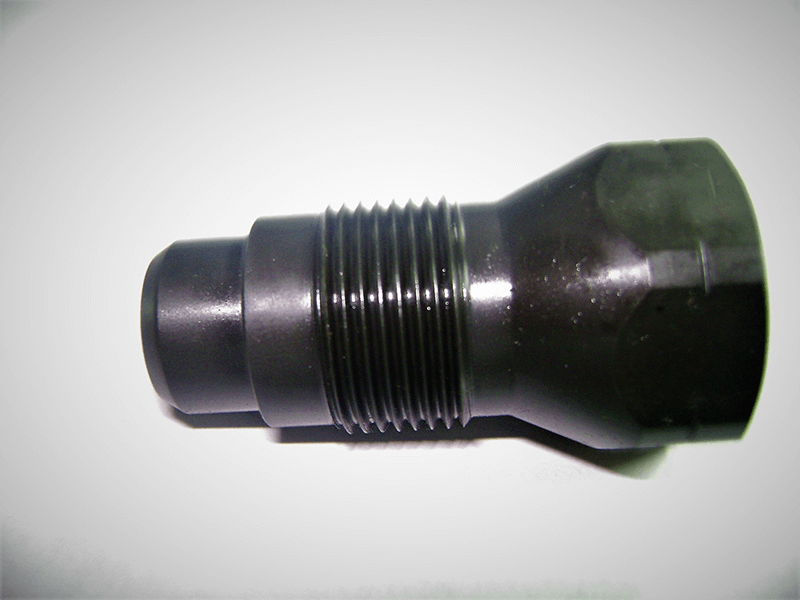

Our Products

Testimonial

ISO/TS16949 Quality System to buy raw material, control the entire machining operations till despatch and usage of documentation like PPAP, ISIR, FMEA, Kaizen, SPC, MSA to control quality. Good quali...

ISO/TS16949 Quality System to buy raw material, control the entire machining operations till despatch and usage of documentation like PPAP, ISIR, FMEA, Kaizen, SPC, MSA to control quality. Good quali...

About us

Geekays Auto Components is a specialist in precision machined supply to the automotive industry, precision CNC turned parts from bar stock, forgings, castings, CNC turning, CNC milling, CNC drilling, 2 axis CNC turning, 2 axis CNC turning with live tools, 5 axis turning with live tools for making complicated parts in single setup treatment, honing, 3 axis CNC drill tap centers, 4 axis vertical machining centers, machining centers with pallet changers for mass production, post machining activities like electroplating, phosphating, high volume mass production set up with accredited quality systems.Materials machined are steel, stainless steel, brass, cast iron, aluminium, and engineering plastic.